Introduction to the Basic Configuration and Function of Z Shape Auto Duct Production Line 7 for Making Square HVAC Duct

Feb 19, 2024

1、 Mechanical composition(General specifications)

Z Shape Auto Duct Production Line 7 for Making Square HVAC Duct is processed in a U-shaped manner,Mainly processing air duct board with a width of 1250mm,Galvanized sheet with a thickness of 0.5-2.0mm (stainless steel 0.5-1.5mm),Main components: material rack machine, host, drum 1, small edge Pittsburgh Lock Forming Machine, large edge Pittsburgh Lock Forming Machine, drum 2 , double-sided angle Steel flange machine, double-sided TDF Flange Forming Machine, and bending machine.

2、 External dimensions and motor power(General specifications)

Machine size

14m*8m

Processing plate thickness

0.5~2.0mm

Processing board width

1250mm

Processing speed

150-200m ²/ hour

Total weight

15t

Total power

45kw

Factory precision

±0.5/4000

Power demand

380v/50hz

Pneumatic pressure demand

6~8

System

Taida

Hydraulic oil

Great Wall 46 # 150L

(1)Material rack:

Function: to carry coil materials and maintain synchronization with the machine head

Single roll carrying capacity ≤ 7 tons

Material core:4 pieces

Shrinkage adjustment outer diameter of Material core pole: 450-620mm

Electrical machinery:1.5kw (4 units)

Size :5800*1800mm

Weight :1800kg

(2)Host:

Function: uncoiling, leveling, pressing reinforcement, cutting square mouth (cutting tip mouth), cutting

Feed port:1 set

Leveling the axis of the reinforcement press:11 pieces

Axis size:Φ 100 * 1420 (plated with hard chromium)

Corner cutting mold:4 sets (2 sets of sharp edges and 2 sets of square edges)

Shear punching plate thickness:0.5-2.0mm

Punching device:1 set (punching lifting holes and flange connection holes)

Manual adjustment of punching mold, one-way double adjustment fixed circular rail (hard rail) Φ 30 aluminum base

Oil pump motor:7.5kw

Variable frequency motor: 5.5kw

Size:2500*2000mm

Weight :2800kg

(3)Drum 1: Function: Conveying the next process

Stainless steel pipe: Φ 76 * 2000 * 2.6mm

Number of drums:30 pieces

Electrical machinery:2 pieces(1.5kw/2.2kw)

Size:2200*4200mm

Weight :800kg

(4)Small edge Pittsburgh Lock Forming Machine

Function: Processing right angle edges(Two mechanical heads can be converted)

Processing plate thickness: 0.5-2.0mm

Roller wheel:9 sets (18 pieces) Bearing steel Material

Roller wheel size:Φ85*44~Φ100*44

Electrical machinery:2 pieces 4kw

Size:950*1400mm

Weight :500kg

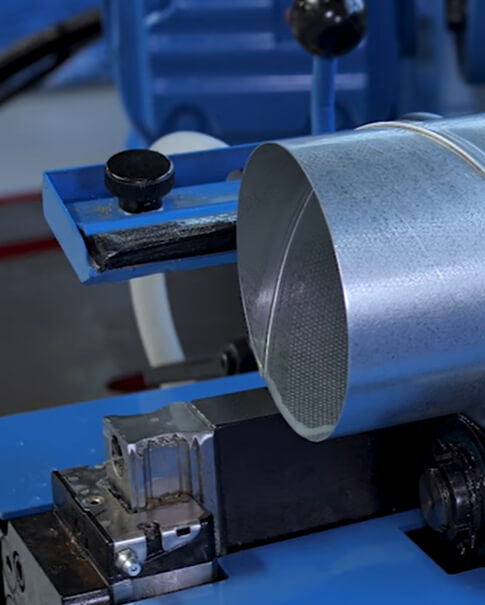

(5)large edge Pittsburgh Lock Forming Machine

Function: Processing pittsburgh lock Forming Machine(Two mechanical heads can be converted)

Processing plate thickness: 0.5-2.0mm

Roller wheel:9 sets (18 pieces) Bearing steel Material

Roller wheel size:Φ85*44~Φ100*44

Electrical machinery:2 pieces 4kw

Size:1400*4200mm

Weight :800kg

(6)Drum 2: Function: Conveying the next process

Stainless steel pipe: Φ 76 * 2000 * 2.6mm

Number of drums:18 pieces

Electrical machinery:3 pieces(0.75kw/0.75kw /1.5kw)

Size:1300*4000mm

Weight :600kg

(7)double-sided angle Steel flange machine

Function: Processing angle steel flange edges

Angle Steel flange machine, manual adjustment, one-way double adjustment, fixed Square rail(hard rail) 30 * 30 * 800

Processing plate thickness:0.5~2.0mm

Roller wheel:unilateral 9 sets (18 pieces) Bearing steel Material

Roller wheel size:Φ85*44~Φ100*44

Electrical machinery: 4kw

Size:2400*1500mm

Weight :1000kg

Belt length:2690*190*5mm,PVC Bright Green

(8)bending machine

Function: Folding L-shaped or air duct bending into shape

Servo motor: 1.5kw

Hydraulic motor:4kw

Planetary reducer:PK80 speed ratio 1:20

Variable frequency motor for conveyor belt:0.75kw

Transmission:Yingweiteng

Size:4800*1800mm

Weight :1300kg

Belt length:8280*150*5mm,PVC grass green anti slip,Origin Shanghai

Mechanical arm cylinder:4 pieces (SC50 * 100 2 pieces,SC50 * 50 2 pieces)