The advantages and Use operation of Spiral duct forming machine?

Oct 16, 2023

A spiral duct forming machine is a piece of equipment used in HVAC manufacturing to fabricate spiral ducts. Spiral ducts are a type of ductwork that features a spiral seam running along their length, giving them a round shape. These ducts are commonly used for ventilation and air distribution in commercial, industrial, and residential buildings.

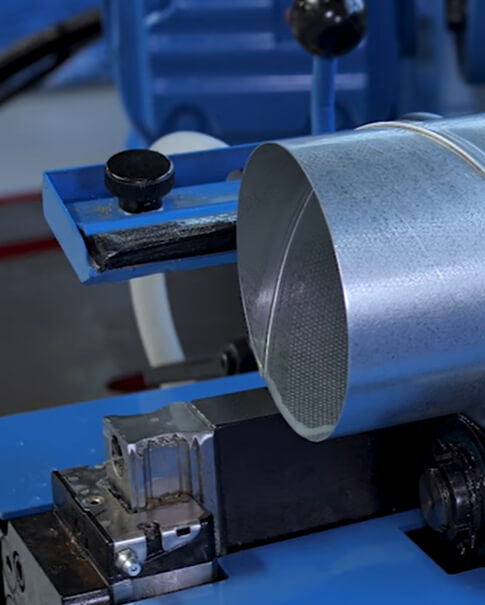

The spiral duct forming machine is designed to automate the process of manufacturing spiral ducts. It typically consists of a coil unwinder, a forming section, a cutting mechanism, and sometimes an additional seam closing station. The machine takes a flat strip of metal, usually galvanized steel or aluminum, and transforms it into a spiral shape.

The process starts with the coil unwinder, which feeds the flat strip of metal into the forming section of the machine. The forming section consists of rollers that gradually shape the metal strip into a spiral, with a constant seam along its length. The machine can adjust the diameter and pitch of the spiral to meet different specifications.

Once the spiral duct is formed, the cutting mechanism cuts it to the desired length. In some machines, there may be an additional station for closing and sealing the spiral seam securely. The finished spiral ducts can then be used for HVAC system installations, connecting to air handling units, or for other ventilation purposes.

Using a spiral duct forming machine offers several advantages, including increased efficiency, accuracy, and consistency in the production process. It speeds up the fabrication of spiral ducts and ensures precise dimensions, resulting in high-quality ductwork for optimal airflow in HVAC systems.