Introduction to duct manufacturing auto line 3

May 28, 2024Advantages of products:

Duct Three production line is composed of rack,leveling embossing machine,blunt pointed mouth and blunt square opening hydraulic punching machine,hydraulic shearing machine,hydraulic folding machine.Electric control part adopts computer control,the control system with a closed loop feed back system,production of precision and stability is improved obviously.The maximum working speed is 16m/min.Error of plus or minus 0.5mm in length, diagonal error of plus or minus 0.8mm.With a high degree of automation,provincial labor,high efficiency and save materials advantages,very suitable of duct processing factory specialized production batch duct.

Main Import Configuration:

1. Electric feeding rack 1(2620*1850*1450mm)

2. Leveling rib pressing device group

3. Hydraulic angle shearing machine,four sets of even die

4. Hydraulic plate shearing device,hydraulic bending device for each group

5. The production of software,a set of computer and control system

Main Technical Parameters:

| Thickness range(mm) | Width(mm) | Max-working speed(m/min) |

Coiler max weight(T) |

Weight(T) | Dimension(mm) |

| 0.5-1.2 | 1300 | 16 | 6000x2 | 3500 | 5000x2160x1450 |

| 0.5-1.2 | 1600 | 16 | 6000x2 | 4500 | 5000x2460x1450 |

Noto:Customers can order the line with different specifications,sheet width and coiler weight.

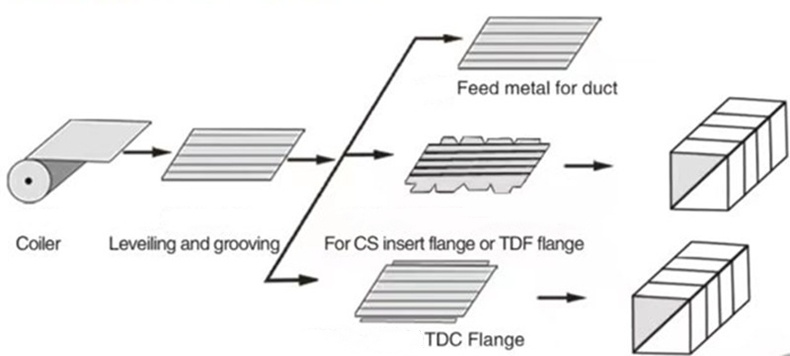

Working Schematic Diagram:

Video presentation: