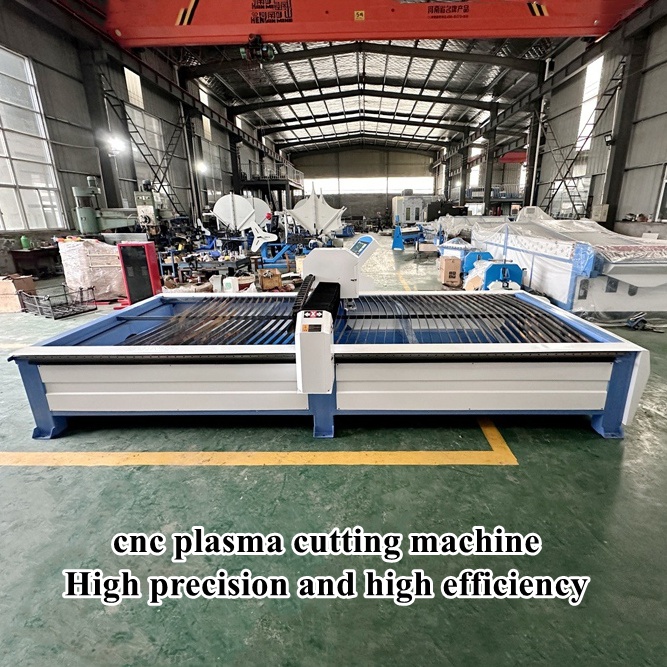

CNC Plasma Cutting Machine

Apr 07, 2024

CNC Plasma Cutting Machine video display

CNC Plasma Cutting Machine Configuration Overview

1.Adopt widely praised CNC cutting special control system, powerful function and simple operation.

2.The unique cutting gun height adjustment device avoids the phenomenon of sticking plate caused by the contact between the cutting gun head and the iron plate.Rolling friction makes the machine run more smoothly and greatly improves the cutting speed.

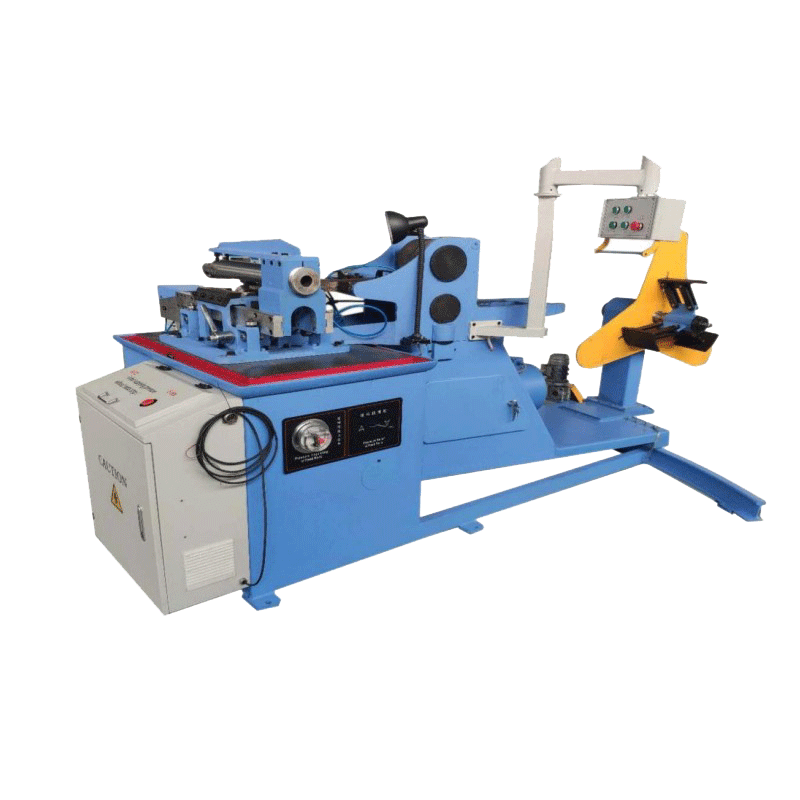

3.Using specialized air duct deployment software, automatically generate drawings and export processing programs.All the operator needs to do is to select the required air duct style in the software, input the required size, and then export the processing program for cutting.It is convenient, fast, accurate and practical.

Hecheng source CNC plasma cutting machine (professional version) configuration overview

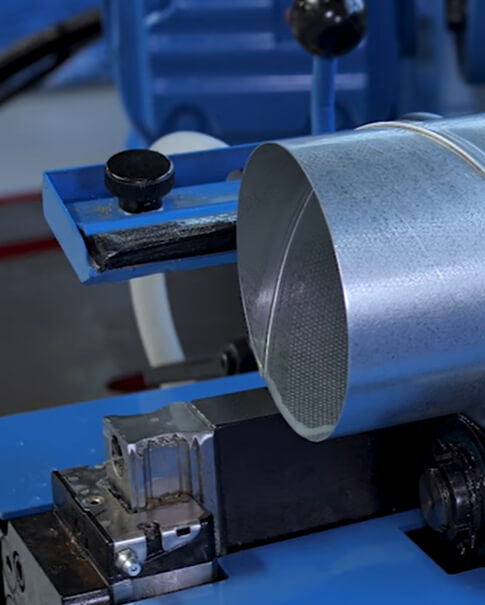

1.Both X and Y axes are driven by rack and pinion. X, Y axis running track adopts precision straight compasses,The accuracy of mechanical operation is ensured effectively. Greatly improve the cutting speed.

2.The unique cutting gun height adjustment device avoids the phenomenon of sticking plate caused by the contact between the cutting gun head and the iron plate.Rolling friction makes the machine run more smoothly and greatly improves the cutting speed.

3.Can use computer direct control, powerful, simple operation, can operate the computer can operate the model of CNC cutting machine.Operators are easy to train, and no longer have to worry about buying equipment that no one can operate.

4.Computer graphics, program production, control processing seamless cooperation, a computer to achieve all functions, saving time, worry, labor.

5.Mechanical limit, electronic limit device each set, so that production no worries.

6.Two-sided drive, equipped with high-power motor, fine drive, with precision machine

Main Technical Parameters

Cutting voltage

380±10%VAC 50Hz

Cutting ways

plasma cutting

Minimum effective cutting range (width x length) mm

1000x 1500

Maximum effective cutting range (width x length)mm

2500x 6000

maximum velocity mm/min

120000

Cutting thickness (plasma)mm

Depends on plasma power supply(0.3-40mm)

Running accuracy

±0.2mm/m

Control mode

U disk transmission, special numerical control system

Kind of drive

Gear, rack, circular rail

Advantages of plasma cutting machine:

Plasma cutting machine is an efficient cutting tool for metal materials, and its advantages are mainly reflected in the following aspects:

1. Fast cutting speed: The cutting speed of plasma cutting machine is usually much faster than that of traditional cutting methods such as gas cutting, especially when dealing with thicker metal sheets, its advantages are more obvious. This helps to improve production efficiency and reduce production time.

2. High cutting quality: plasma cutting machine uses plasma as a heat source, can produce high energy density, so that the cutting surface is flat, smooth, small incision, no burrs, high precision. This is particularly suitable for applications where high precision cutting is required.

3. Wide range of applications: Plasma cutting machine is suitable for cutting various metal materials, including steel, aluminum, copper, titanium, cast iron, etc., can meet the needs of different industries.

4. Large cutting thickness: Compared with laser cutting, the plasma cutting machine has a wider range of cutting thickness, especially for thicker materials such as steel plates and stainless steel plates, and the cutting effect is better.

5. Simple operation: The operation of the plasma cutting machine is relatively simple, and the skill requirements of the operator are not high, which reduces the labor cost.

6. Low cost: Compared with high-end cutting technology such as laser cutting and water cutting, plasma cutting machine has lower cost and relatively less maintenance cost, which is suitable for small and medium-sized enterprises.

In addition, the plasma cutting machine also has the advantages of good stability, easy arc starting, light weight, small size, easy to move and so on. However, the plasma cutting machine also has some shortcomings, such as arc intensity, loud noise, dust, and certain pollution to the environment, and the number of cutting guns should not be too much, otherwise it may affect the cutting quality. Therefore, when choosing the use of plasma cutting machine, it is necessary to comprehensively consider the specific application needs and environmental conditions.