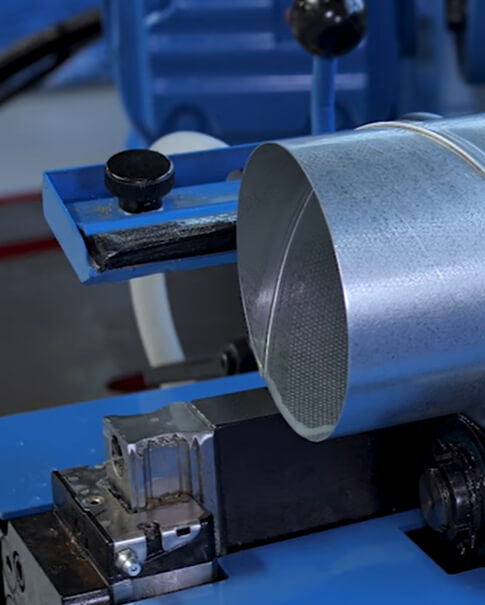

Elbow making machine, also called round elbow locker machine. it is the special equipment for both connecting lock and seaming when processing on metal plate round pipe and round elbow. By adjusting the position of pointer on the hand wheel, two locks will be formed separately at the mouth of the round pipe then connect the mouth of the pipe for two locks on the other set of the roller to form an elbow. Featured with durable structure, high performance and efficiency and easy-operation, this elbow making machine can form accurate dimension and right angle, and this type of lock is more air-tight with better seam.

Good quality forming and seaming are achieved by one machine and space is saved.

HS Code :

8455229090Min. Order :

One SetManufacturing Time :

Almost IN STOCKPayment Terms :

TT,LC,West Union etcPacking Method :

Exporting wooden boxQuality Guarantee Period :

18 month from B 'L issued dateAnnual Production Capacity :

200 sets machinesCUSTOMER DESIGN OR OEM :

AcceptedRound Duct Electric Elbow Making Machine

I. Elbow Making Machine's Features:

Elbow making machine is used for circular tube elbow bend(shrimp)docking bite on special equipment.Pipe diameter range from 100-1000mm.Minimum can do 100mm diameter,sealing good shape appearance at the same time is also very beautiful.

Elbow making machine mainly used air conditioning hvac.

1. Elbow making machine with dual working station.

2. Max. flexibility – eliminates equipment’s changing over and reduces tool’s changing.

3. Higher production speed.

4. Flanging speed Up to 4m per minute.

5. Higher capacity.

6. Material thickness: up to 1.5mm Galvanized steel &1.0mm stainless steel.

7. Improved seam’s quality.

8. Optimized roller’s profile.

9. Virtually no maintenance.

10. No lubrication & all rotating parts made of hardened, high grade steel.

11. Manufacture of segment bends, reducers, end covers and offsets & attachment of cams forMETU system.

12. 2 separate workstations achieve high flexibility: a flanging station and a closing station. machine is always ready for operation without time-consuming conversion.

II. Technical Parameters

1. Machine name: Round duct electric elbow making machine

2. Model: HCY-1000

3. Max. thickness: 1.2mm

4. Dia. range: 100-1000mm

5. Forming speed: 7r/min

6. Motor power: 1.5kwx2

7. Weight: 556kg

8. Dimension: 2100x820x890mm

III. Real Photos:

IV. Quality Certifications:

V. RFQ:

1. Are you manufacturer or trading company?

We are manufacturer.

2. What shall we do if don't know how to operate your machine?

We can dispatch our engineers to your country and you can also send your engineers to our factory for learning operation. Besides, there are detailed installation and operating instructions attached, it is very simple. We have telephone and email support at 24 hours per day.

3.How about your machine quality?

HCY company is a mature brand in CHINA,through our 15 years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry And where there are our machines,there are good reputation and terminal user satisfaction.

4. What are your payment terms?

We support T/T, L/C, D/P, D/A, Western Union and so on. TT, 30% in advance, 70% balance before the shipment.

5.Can we be your agent?

Yes,we are looking for Global agent we will help agent improve the market ,and supply all the service like machine technical

problem or other after-sales problem, meanwhile ,you can get big discount and commission.

6.Do you accept customer Logo and customized ?

we accept kinds of customized ,including logo and machine .

Hot Tags :